Line Stopping Service

Line Stopping Service

Line Stopping Service

Line stopping is an essential service in the pipeline industry that allows for necessary repairs, maintenance, or modifications without shutting down the entire system. Since 1997, Watertap, Inc. has specialized in providing quick and efficient water main shutdown and bypass services to municipalities and contractors alike. Our line stop options vary in size from 1.5 to 66 inches, catering to a diverse range of pipeline specifications. With over 25 years of dedicated service, Watertap, Inc. has become one of the country’s most trusted names in safe and efficient line stopping solutions.

What are the Benefits of Line Stopping?

Line stopping is a preferred method for many pipeline projects due to its non-disruptive nature. The benefits include:

- Continuous Operation: The pipeline can continue operating without service interruption. This is crucial for industries and municipalities that rely on a consistent supply of water. By maintaining flow in the main pipeline, we ensure that essential services remain available during maintenance operations.

- Versatility: Suitable for various pipe materials and pressures up to 900 psi at 100ºF, and temperatures up to 300 psi at 375ºF. This adaptability makes line stopping an effective solution for a wide range of pipeline systems, from municipal water mains to industrial chemical pipelines.

- Cost-Effective: Reduces downtime and service disruption, leading to significant cost savings. Avoiding a full system shutdown minimizes the economic impact on businesses and municipalities, as operations can continue as normal during repairs.

- Reduced Risk: Minimizes the risk of water main contamination and infrastructure damage. Line stopping isolates only the section of the pipeline being worked on, reducing the likelihood of introducing contaminants or causing additional wear and tear on the system.

- Efficiency: Saves time and resources by allowing for targeted interventions. Because line stopping is a precise and controlled method, it enables quick and effective repairs or modifications, minimizing the duration of maintenance activities.

Compatible Pipe Materials

- Cast Iron

- Ductile Iron

- PVC

- HDPE

- Galvanized

- Asbestos Cement/Transite

- Pre-Stressed Concrete Cylinder

- Non-Cylinder Concrete

- Stainless Steel

- Steel and Copper

Suitable Products

- Water

- Glycol

- Sewer

- Chilled Water

- Re-Use Water

- Brackish Water

- Compressed Air

Line Stop Applications

- New Construction Tie-ins

- By-Pass Piping Installation

- Pipe Inspection

- New Pipeline Construction

- Sample Points for Quality Control

- Watermain Break

- Flow Meter Installation

- Thermowell Insertion

Contact Us Today For A Free Consultation

Why Choose Watertap, Inc?

- Comprehensive Line Stop Range: Choose from 1.5″ to 66″ line stops for tailored pipeline service management.

- Versatile Stop and Bypass Capabilities: Our services include multiple options for both stopping and bypassing the water flow, ensuring uninterrupted service.

- Extensive Inventory: Benefit from our large, ready-to-ship inventory to meet your immediate line stop needs.

- Compatible with Various Pipe Materials: Our line stops are suitable for a wide variety of pipe types including concrete, ductile/cast iron, high-density polyethylene (HDPE), carbon steel, and C900.

What is the Line Stopping Process?

Line stopping involves creating a temporary shut-down point in an existing pipeline without interrupting service. This process allows for targeted repairs or modifications to be made while the rest of the system continues to function normally. Here is a detailed look at our process:

- Assessment: Our team conducts a thorough inspection and planning session to understand the specific needs of the pipeline system. This initial step ensures that we tailor our approach to the unique characteristics of your infrastructure, identifying the optimal points for line stopping and the appropriate equipment to use.

- Installation: A special flanged fitting and a temporary valve are installed and tested to ensure they can withstand the pipeline’s operating conditions. This setup allows us to isolate the section of the pipeline that requires maintenance or modification.

- Hot Tapping: Once fitting is installed and tested to insure that it will handle pipeline’s operating conditions. The hot tap machine is mounted to the temporary valve to start drilling. Once the tap machine has drilled out a section of existing pipe, the temporary valve is shut and the tap machine will be removed.

- Line Stop Actuator Setup: The folding/pivot head is inserted into the line to halt water/product flow. The actuator drives the folding/pivot head into position, creating a seal that prevents the flow of water or other substances through the section of the pipeline being worked on.

- Completion: After the necessary work is done, the stopping head is removed, a completion plug is set, removal of temporary valve and a blind flange is installed to restore the pipeline to its original function. This ensures that the pipeline can resume normal operations without any leakage or loss of integrity.

Products and Brands We Use

At Watertap, Inc., we prioritize the use of high-quality products and reputable brands to ensure the reliability and efficiency of our line stopping services. Our commitment to excellence drives us to select the best tools and equipment in the industry, enabling us to deliver superior results for our clients.

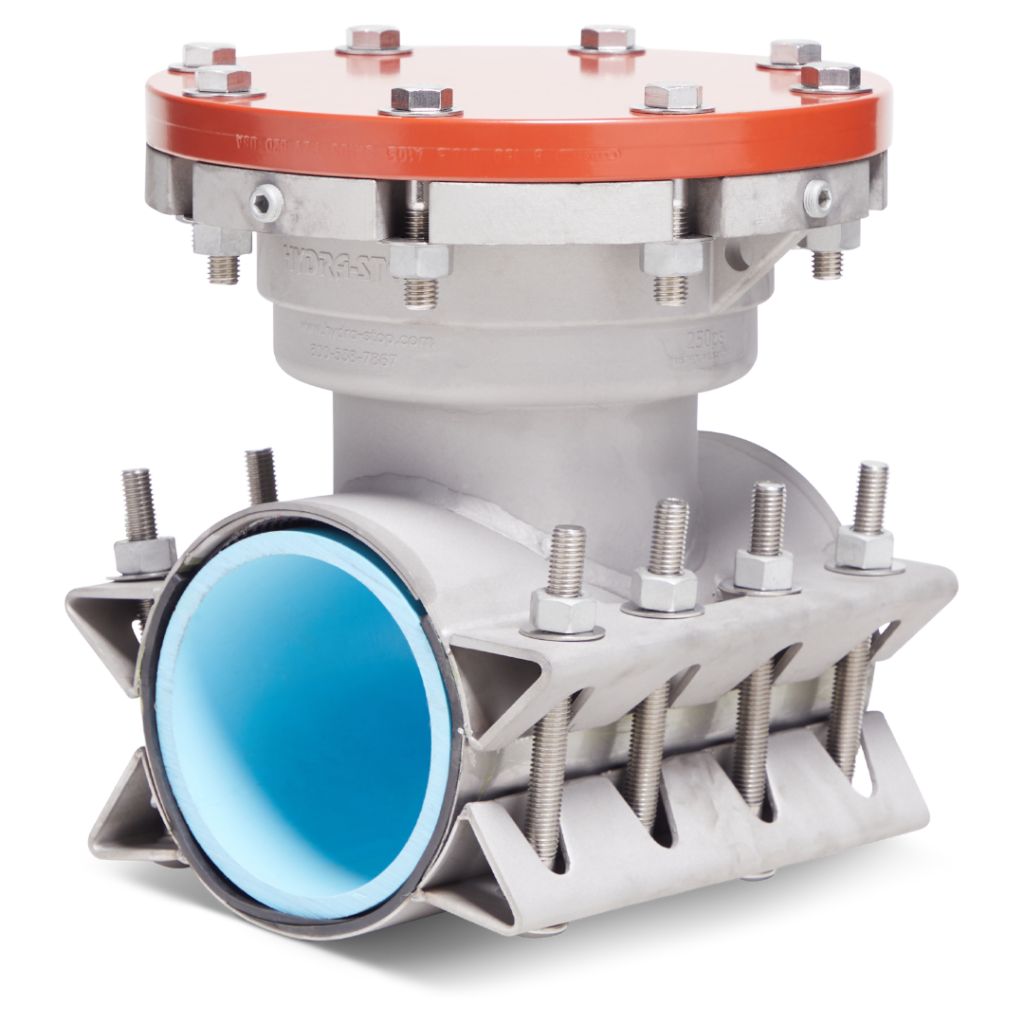

We utilize Hydra-Stop’s HSF 250 Patriot Line Stop system, known for its durability and innovative design. Hydra-Stop is a leader in the pipeline maintenance industry, offering solutions that allow for maintenance and modifications without shutting down the entire system. The HSF 250 Patriot Line Stop system is engineered to handle high pressures and provides a reliable seal, ensuring minimal disruption during pipeline repairs and modifications.

Spec Sheets

Submittals

JCM Industries is another trusted brand we rely on for line stopping products. Their range of line stop fittings, including the 4-12 inch, 14-20 inch, 24 inch, and 30-42 inch models, are designed to accommodate various pipeline sizes and materials. JCM’s products are known for their robust construction and ease of installation, making them ideal for both emergency repairs and planned maintenance.

Submittals

Reliant Pipeline Products provides a variety of line stop fittings that we use for our services. Their fittings are compatible with different pipeline materials and sizes, including the 4-12 inch and 16-20 inch models. Reliant’s line stop solutions are designed to offer reliable performance under various operating conditions, ensuring the integrity of the pipeline during maintenance activities.

Submittals

FAQ

What types of line stops do you offer?

We handle everything from water mains to sewage lines and industrial pipelines. Contact us for more information.

How long does the line stopping process take?

The duration varies based on the project’s complexity. Our team provides a time estimate after the initial assessment.

Is line stopping safe for all pipeline materials?

Yes, our techniques and equipment are designed to work safely on various pipeline materials.

Additional Services and Applications

Our expertise extends to various pipeline materials, including cast iron, ductile iron, PVC, HDPE, and more. This diverse material handling capability allows us to provide tailored solutions for any pipeline infrastructure, maintaining the highest standards of quality and performance.

In addition to line stopping, Watertap, Inc. offers a comprehensive range of services to meet diverse pipeline needs:

Live Taps

We perform live tapping services, allowing for new connections to existing pipelines without interrupting service. This technique is crucial for adding branches to active pipelines efficiently and safely.

Valve Insertions

Our valve insertion services provide a permanent solution for adding control points within your pipeline system, using advanced methods to avoid shutdowns and service disruptions.

Emergency Services

We offer rapid response for urgent pipeline issues, ensuring minimal downtime and swift resolution of critical problems

Get in Touch with Our Experts

Ready to experience the Watertap, Inc. difference? Contact our experts for top-tier line stopping, live taps, and valve insertion services.

Contact Us Today For A Free Consultation